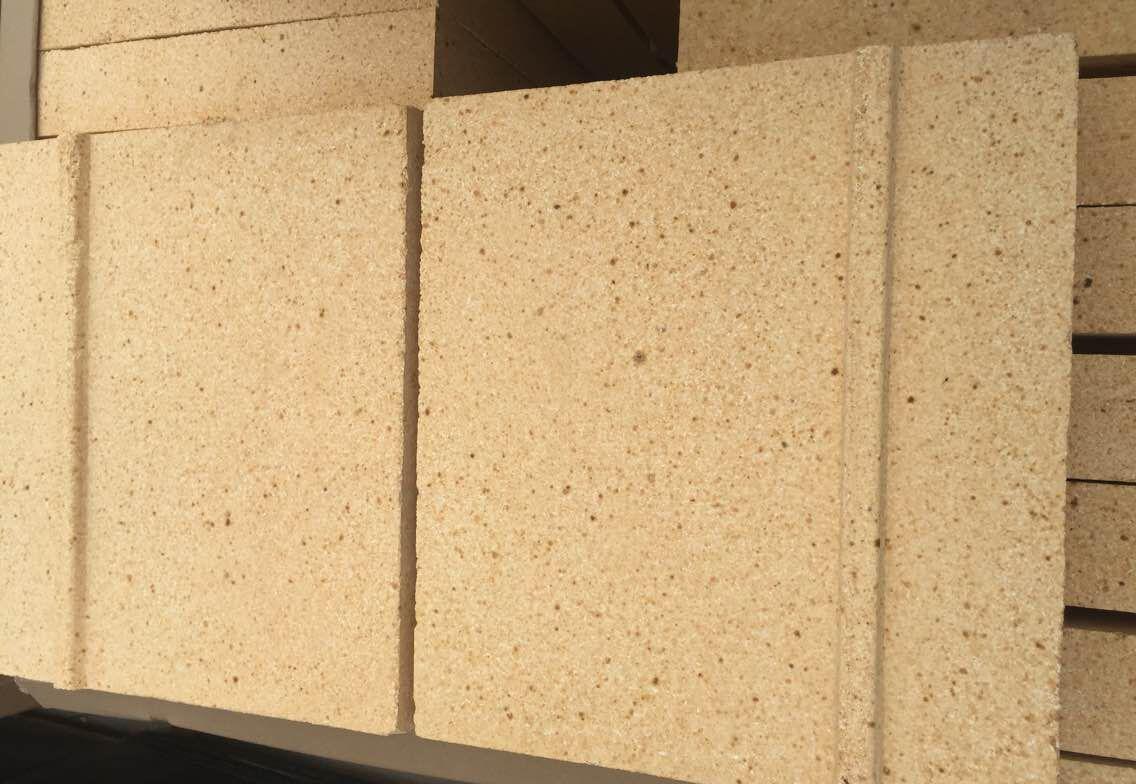

Fire clay bricks are sticky soil products which refer to Al2O3 containing 30%~40% aluminum silicate material. The main mineral composition of fire clay bricks are kaolinite and 6%~7% impurities(oxide of potassium, sodium, calcium, titanium and iron). Fire clay bricks adopt 50% soft clay and 50% hard clay clinker, ingredient by a certain size, and sinter under high temperature of 1300~1400℃ after forming and drying. The sintering process is mainly the process of decomposition of kaolinite which continuously dehydrates to mullite. SiO2 and Al2O3 form eutectic low melting point of silicate with impurities in the process of sintering and surround the mullite crystal around.

Features and advantages:

1.High refractoriness,

2.High-temperature endurable .

3.Good corrosion resistance.

4.Good spalling resistance and wear resistance.

5.Good thermal shock resistance.

6.High mechanical strength.

7.High-temperature creep rate is low.

8.Good volume stability at high temperature.

|

Item |

Fire Clay Brick |

Lower Porosity clay brick |

||

|

Al2O3 |

≥40 |

≥42 |

≥42 |

≥45 |

|

Refractoriness ºC |

≥1710 |

≥1750 |

|

|

|

0.2MPa Refractoriness under load ºC |

≥1320 |

≥1400 |

≥1470 |

≥1500 |

|

Permanent liner change% |

1350ºC×3h+0.2~-0.5 |

1400ºC×2h+0.1~-0.4 |

-0.2~+0 |

+0.05~-0.1 |

|

Apparent Porosity % |

≤24 |

≤22 |

≤15 |

≤12 |

|

Cold crushing strength Mpa |

≥19.6 |

≥29.4 |

58.8 |

68 |

|

Bulk Density g/cm3 |

2.1 |

2.15 |

2.3 |

2.37 |