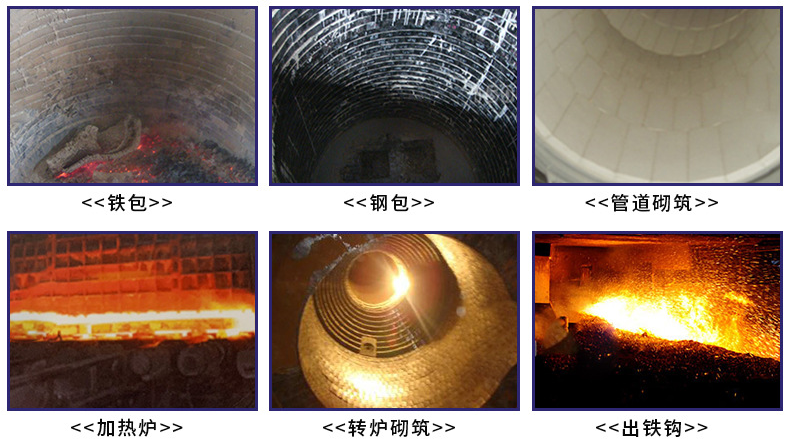

High-aluminum castable refers to a refractory castable with an Al₂O₃ content greater than 48%. It has the characteristics of high cold and hot strength, good wear resistance, heat shock resistance, peeling resistance, and good volume stability at high temperatures. It has a wide range of applications, including cement kiln heads, kiln tails, cyclone preheaters, tertiary air ducts, grate coolers, refining furnace covers, blast furnaces, heating furnaces, etc.

Traditional lightweight high-aluminum castables have large pore diameters and high thermal conductivity, so they can only be used at low temperature (≤1200°C) locations. It can be known from the traditional theory that if the material can form a closed circular micro-pore structure, its thermal conductivity can be significantly reduced. In order to improve the performance of lightweight high-aluminum castables, during work, high-performance lightweight high-aluminum castables with lower thermal conductivity, higher strength and volume stability have been developed by adding pore formers.

The scientific formula further improves the high-temperature strength and thermal stability of the castable refractories, effectively controls the calcium oxide content, reduces the eutectic phase of the material, and improves the refractoriness, high-temperature strength and slag resistance. This series of castables is based on the combination of refractory and high-aluminum raw materials, and adopts the new technology of adding micropowder and high-efficiency compound chemical additives. The characteristics of high load softening temperature, long life, convenient construction, etc., have obvious effects on improving heat preservation, reducing heat loss, and lowering environmental working temperature.

Suitable for heating furnaces, soaking furnaces, heat treatment furnaces, rotary kilns; all kinds of high-temperature burner linings, heating furnace water pipe wrapping linings, steel furnace external refining device parts and high-temperature wear-resistant linings of petrochemical catalytic cracking reactors; blast furnaces The lining of the iron tapping trough, the iron furnace tapping trough, and the integral powder spray gun for hot metal pretreatment. It can also be used to make large prefabricated blocks and furnace linings to facilitate rapid construction.