Wear-resistant plastic is an important variety of unshaped refractory materials. It is made of refractory aggregates, fine powders, composite additives, and cementitious binders through mixing and extrusion. Mass material, construction by ramming method, the plastic has high high temperature strength, good thermal shock stability and low thermal conductivity. It is used to ram a seamless furnace body, which has strong integrity, good peeling resistance and long service life. Long and energy saving, it has been widely used in the lining of various high-temperature industrial kilns such as heating furnaces, soaking furnaces, heat treatment furnaces, etc. It has convenient construction, rapid repair, high-strength wear-resistant, and good thermal shock performance. , No cracks, good airtightness. Mainly used for repairing fluidized bed boilers.

Product Features:

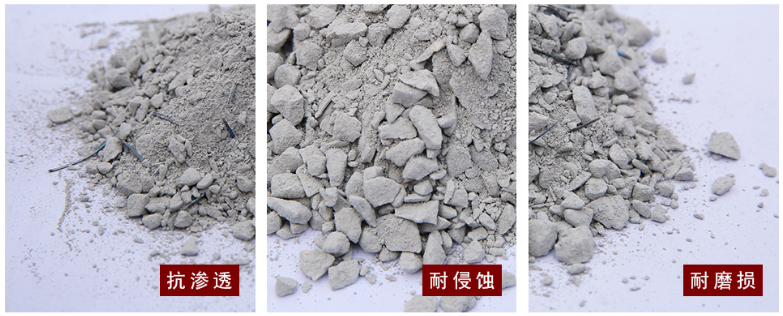

The wear-resistant and refractory plastic has high strength, excellent corrosion resistance, long shelf life, and convenient construction and oven. It is suitable for the wear-resistant lining of various CFB boilers. The use of this material in maintenance can shorten the oven time. The plastic can be made into flakes and blocks. Certain bonding agents can also be added during construction.

When in use, the mixture is compacted or rammed, and after baking, a dense lining and structure can be formed. Good plasticity before hardening; strength after hardening. It has good sinterability, volume stability and other high-temperature properties at high temperatures. It is in the form of hard clay paste, and maintains high plasticity for a long time. It contains more plastic clay components and has more water than ramming materials. It is mainly used in various heating furnaces that do not directly contact the molten material. The materials are mostly clay and high aluminum, but also silicon, magnesia, chromium, zircon and silicon carbide.