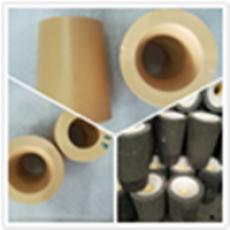

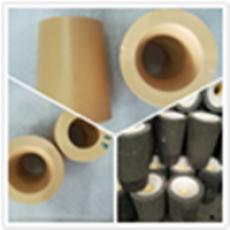

Zirconia Material inner insert nozzle for tundish nozzle in steel industry

Tundish nozzle zirconia inserts for industrial oven are made of

zirconia and imported baddeleyite,formed by high tension and baked in

high temperature when stablized by special technology. Different sizes

and types of tundish nozzle zirconia inserts are designed and made

according to users' different steel-making conditions and requirements

You may submit your questions by filling the form.

Zirconia Material inner insert nozzle for tundish nozzle in steel industry

Tundish nozzle zirconia inserts for industrial oven are made of zirconia and imported baddeleyite,formed by high tension and baked in high temperature when stablized by special technology. Different sizes and types of tundish nozzle zirconia inserts are designed and made according to users' different steel-making conditions and requirements.

Features of Zirconia Material inner insert nozzle

1.Low expansion, supprior resistance to erosion/corrosion and thermal shock cycling.

2.Long and extended casting sequence times

3. Controlled and stable casting speed

4.Resistance to oxygen lancing

5.changeless diameter and lasing long.

Technical index of Zirconia Material inner insert nozzle:

Item

| Tech spect(%)

|

ZrO2

| 95.0

|

MgO

| 3.0

|

CaO

| 1.0

|

Density(mg/cc)

| 5.27

|

A.P.(%)

| 6.0

|

Application

In casting steel Zirconia Material inner insert nozzle are mainly used in successive-casting intermediary small square adobes, big square adobes, rectangle adobes and small board adobes.

Packaging & Shipping

Packaging detail:

Zirconia Material inner insert nozzle are packed on wooden pallet and then polyethylene film is placed over it, finally the package is tied up with steel strips or as your request.

Shipping detials:

15-30 days after the payment.

About Us

1. Strong professional:

Our company has thirty years producing experience in refractory products. Our manager will supervise on a various refractorys production materials, process control, quality supervision and package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system certification and SGS certification. And the annual supply of shaped and unshaped refractory product is 28, 800-35, 000 tons.

3.Export experiences:

Now we have gained a global sales network reaching Taiwan, Russia, Korea, Vietnam, Pakistan, Bulgaria, French, India, Egypt,Congo, Angola, South Africa, and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

5. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

HOME

HOME