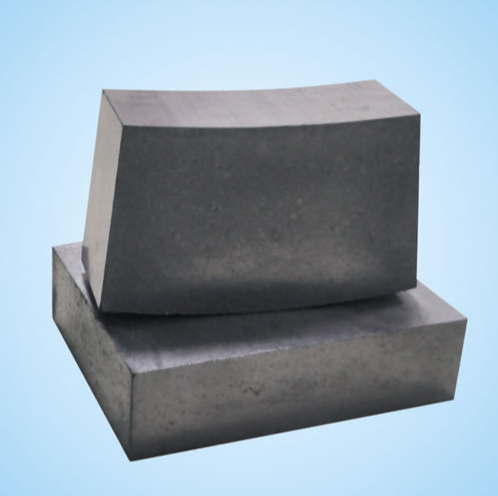

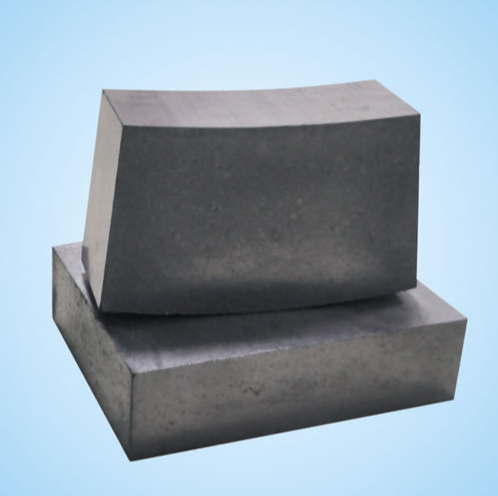

Magnesia Carbon Bricks

Magnesia Carbon

Bricks, a kind of unburned carbon composite refractory, are manufactured

with magnesium oxide of alkaline oxide with high-melting-point (2800℃)

and carbon material with high melting point that is difficult to be

eroded by furnace slag as the raw materials, and added all kinds of

non-oxides additive and carbon binding agent.

You may submit your questions by filling the form.

Description for Magnesia Carbon Bricks

Magnesia Carbon

Bricks, a kind of unburned carbon composite refractory, are manufactured

with magnesium oxide of alkaline oxide with high-melting-point (2800℃)

and carbon material with high melting point that is difficult to be

eroded by furnace slag as the raw materials, and added all kinds of

non-oxides additive and carbon binding agent.

As a kind of

composite refractory, Magnesia Carbon Brick utilizes strong slag

corrosion of magnesia and high thermal conductivity and low

expansibility of carbon efficiently, which make up for the biggest

disadvantage of worse spalling resistance of magnesia.

Magnesia Carbon Bricks Properties

Good high temperature resistance property

Strong slag erosion resistance

Good thermal shock resistance

Low high-temperature creep

Good heat stability

Good thermal conductivity

Magnesia Carbon Bricks Manufacturing Process

Traditional

magnesia carbon bricks that are manufactured according to cold mixing

techniques with compound tar binding agent becomes harden and gets the

necessary strength. Thus form isotropous vitric carbon. This kind of

carbon does not show the thermoplasticity that can duly remove amount of

stress in the process of lined firing or operating. Magnesia Carbon

Bricks are made of pitch binding agent, which has higher high

temperature plasticity because of forming anisotropic graphitization

coke structure in the pitch carbonation process.

Magnesia Carbon Bricks Uses

Magnesia

Carbon Bricks are mainly used for linings of converter, electric-arc

furnace and direct current electric arc furnace, slag line of steel

ladle and other position.

Magnesia Carbon Bricks Composition

Magnesia

Carbon Bricks are a kind of quality refractory materials. Their main

components are magnesium oxide and carbon, of which magnesium oxide

content is 60~90% and carbon content is 10~40%. This kind material is

made of high purity magnesia particle, carbon material, tar, pitch or

resin as the raw materials through high temperature baking. Magnesia

Carbon Bricks have properties of slag corrosion resistance, thermal

shock resistance, thermal conductivity and etc.

Physical And Chemical Index Of Magneisa Carbon Bricks

Magneisa Carbon Bricks |

| Item/Index | MGC-10 | MGC-12 | MGC-15 | MGC-18 | MGC-20 |

| Bulk Density (g/cm3) | 2.95 | 2.90 | 2.85 | 2.80 | 2.78 |

| Apparent Porosity (%) | 3~5 | 3~5 | 3~5 | 3~5 | 3~5 |

| Compressive Strength (kg/cm2) | 450 | 400 | 400 | 350 | 350 |

| Expansion at 1000 ℃ | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 |

| Chemical Composition (%) | MgO | 86 | 84 | 80 | 76 | 74 |

| F.C. | 10 | 12 | 15 | 18 | 20 |

| Application | Ladle | EAF Ladle | BOF EAF Ladle | BOF EAF LF | BOF EAF |

HOME

HOME